Heat transfer options

The table below gives an overview of the different heat transfer options we have tested

|

Thermal conduction

Energy transfer through conducting fins can be an option for

the cases when a cooker or a fryer is in the form of a hot

plate.

|

|

Forced convection with a heat transfer fluid

A pump or a fan can be used for circulation of the heat transfer fluid. We try to avoid pumps and fans, as it reduces the robustness of the system and requires power (battery for off-sun periods). However, we have experience with some cases:

|

|

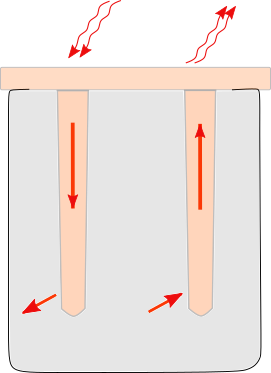

Natural circulation with a heat transfer

fluid

Hot oil has less density than cold and the

density difference can induce natural circulation between the

heating part of the system and the heat extraction part (the

cooker).

|

|

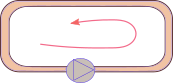

Liquid-vapor thermosyphon

A heat transfer fluid can evaporate at the

hot side and condense at the cold side (the cooker). The

condensate drains by gravity back to the hot side. This

gives efficient heat transfer as the temperatures on the hot and

the cold side in the ideal case are equal.

|

|

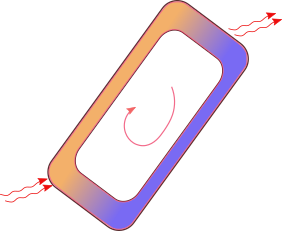

Heat pipes

A thermosyphon type of heat transfer can be

obtained using a single pipe with counter-current upwards vapor

flow and downwards gravity driven condensate flow. The term

"heat pipe" is, however, mostly used for the case where the

liquid transport is in a wick, in which case it can also work

for horizontal pipes.

|

|

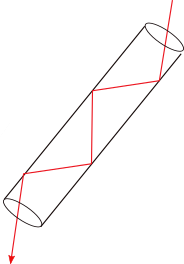

Light guides

Internal reflecting tubes can guide incoming

rays to the tube outlet. The inlet can be positioned in the

focal point of a dish concentrator and an absorber can be

positioned at the outlet.

|