TMM4175 Polymer Composites

Compression testing¶

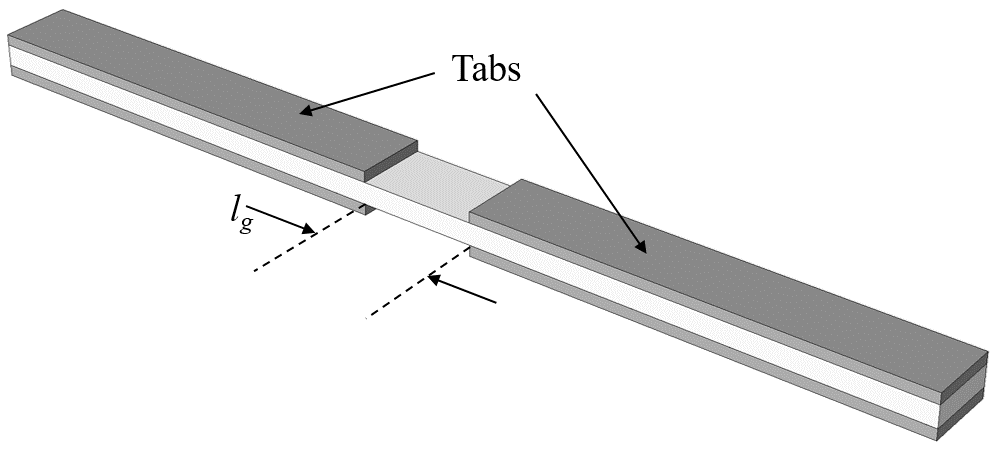

Compressive testing of composites is notoriously difficult. The mode of failure involves a mixture of global column buckling of the entire specimen, to local micro buckling of the individual fibers. End loaded specimens tend to split from the ends and indirect loading by means of shear is often used. Shear loading introduces other challenges where failures often initiate at the grips due to stress concentration in this area. The test methods tend to underestimate the intrinsic compressive strength of the composites. Many axial compression test methods are some variation of the Celanese compression test described in ASTM D3410. In this method, a thin, straight-sided specimen with a small gauge length is loaded in the tabbed region using inverted cone wedge grips. The IITRI fixture shown below, which is a minor modification, incorporates flat wedge surfaces rather than conical surfaces for greater stability.

Tabs bonded to the specimen are recommended when testing unidirectional materials in the fiber direction. Transverse compression testing can however often be successfully conducted without tabs.

The ASTM D3410 Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading specifies the combination of specimen dimensions with respect to various stiffnesses and expected failure strength. The required minimum thickness (h) for the unidirectional E-glass/Epoxy loaded in the fiber direction and having a gauge length lg is given by:

E1 = 40000

Xc = 700

G13 = 3800

lg = 15

h = lg/(0.9069*((1-1.2*Xc/G13)*(E1/Xc))**0.5)

print('Minimum thickness = ',h, 'mm')

In the above relation, Xc is the expected compressive strength. If the material data is based on anything but the maximum value obtained (such as mean, characteristic, etc), we should increase this value:

Xc = 1000

h = lg/(0.9069*((1-1.2*Xc/G13)*(E1/Xc))**0.5)

print('Minimum thickness = ',h, 'mm')

More on this test method in the case study Compression testing of UD composites

Disclaimer:This site is about polymer composites, designed for educational purposes. Consumption and use of any sort & kind is solely at your own risk.

Fair use: I spent some time making all the pages, and even the figures and illustrations are my own creations. Obviously, you may steal whatever you find useful here, but please show decency and give some acknowledgment if or when copying. Thanks! Contact me: nils.p.vedvik@ntnu.no www.ntnu.edu/employees/nils.p.vedvik

Copyright 2021, All right reserved, I guess.