TMM4175 Polymer Composites

Tensile testing¶

Uniaxial tensile tests are conducted on unidirectional laminae to determine the longitudinal and transverse Young's moduli $E_1$ and $E_2$, the Poisson's ratios $\nu_{12}$ and $\nu_{21}$, the basic longitudinal and transverse strength parameters $X_T$ and $Y_T$ as well as coresponding failure strains.

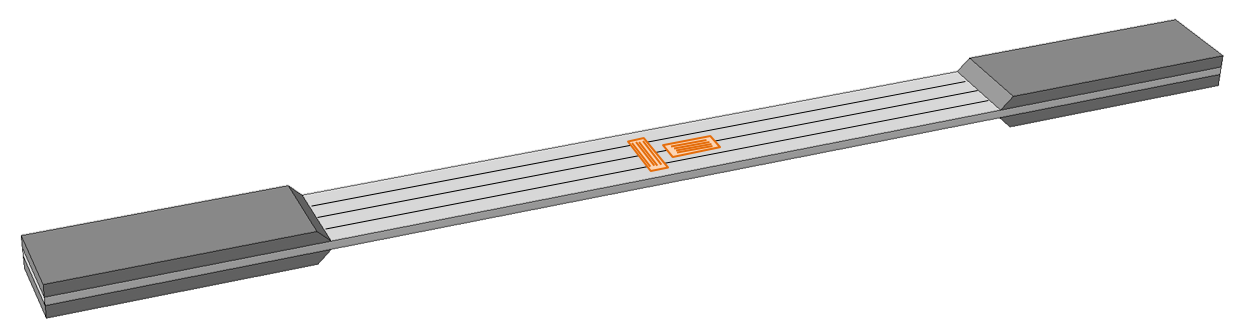

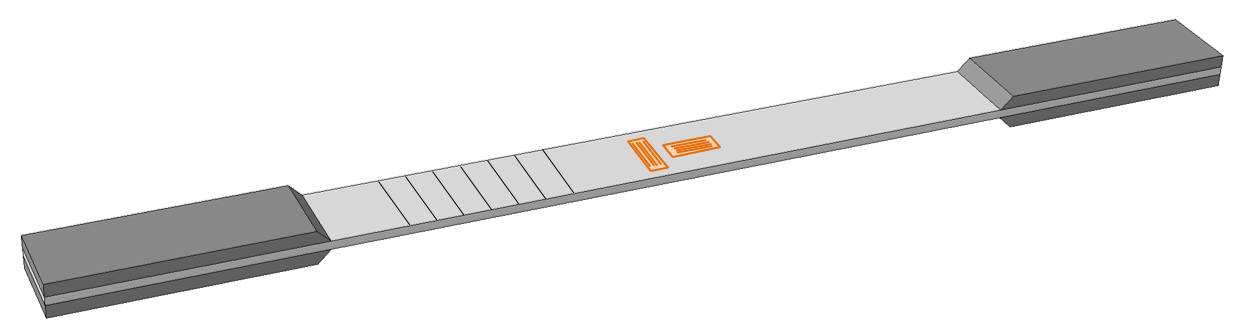

The measurements of these properties is in theory very simple: A thin strip of a UD composite is placed into the grips of a mechanical testing machine and loaded slowly in tension. To determine the modulus of elasticity and Poisson’s ratio, strains are measured during the initial stage of the test, using strain gages as illustrated in Figure-1 and 2 or extensometers. Loading continues to ultimate failure, the point at which tensile strength and ultimate tensile strain are obtained.

In practice, however, obtaining valid results for strength parameters is not always easy.

Figure-1: Tensile test specimen with tabs for longitudinal direction of UD laminae.

Figure-2: Tensile test specimen with tabs for transverse direction of UD laminae.

Generally, tensile specimen must be designed in such a way that stress during the test will be greater in the central test section than in the clamped regions at the end. For isotropic materials, the width of the specimen is gradually reduced from the ends into the central gauge length section, typically referred to as a “dog-bone” specimen. In the case of UD composites this is not an option since axial splitting of the specimen will occurs well before ultimate failure, effectively producing an untapered specimen. These axial cracks result from the relatively low shear strength of the UD composite material combined with relatively high shear stresses in these regions.

The solution for composites is usually to add bonded tabs on the ends. When a tabbed tensile specimen is tested, the load is transferred through shear at the gripped tab surfaces. The tabbing material and the adhesive bond must have shear strength adequate to transfer the load into the composite to produce failure while simultatneously prevent axial cracking and stress consentration. An effective means of minimizing the stress concentration is to use a carefully choosen taper angle as illustrated in Figure-1 and Figure-2.

Disclaimer:This site is about polymer composites, designed for educational purposes. Consumption and use of any sort & kind is solely at your own risk.

Fair use: I spent some time making all the pages, and even the figures and illustrations are my own creations. Obviously, you may steal whatever you find useful here, but please show decency and give some acknowledgment if or when copying. Thanks! Contact me: nils.p.vedvik@ntnu.no www.ntnu.edu/employees/nils.p.vedvik

Copyright 2021, All right reserved, I guess.