Temperature control: valves

A valve is required in order to open for a hot oil into the storage at a given set temperature.

The valve is subject to the same requirements as for the heat storage systems: it should be simple, robust and possible to construct and maintain locally.

Some experiences we have are illustrated below.

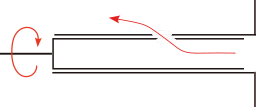

| Rotating tubes A rotating tube is placed inside a stationary tube and both are open for fluid entry at one end. The inner tube is closed and rotated by an actuator (bi-metal spring). When two holes in the pipe align, fluid enters form outside and through the holes. The longer the tubes, the better the sealing. |

|

| Pistons Tubes with moving pistons passing a hole in a tube has been used with two types of actuators: a floater (to keep constant fluid level) and expansion of oil in an attached coil immersed into the oil to be temperature controlled. |

|

| Sliders Sliders have been applied for our cases where the valve should have two outlets, one cold and the other hot. Sliders have been made with flat sliding plates, and with standard square profiles. Horizontal sliders require less force than vertically moving covers, which would be susceptible to the pressure difference across the valve. |

|