596f Thermally Integrated Micro-Channel Fuel Processor

There is considerable interest in the development of microchannel based fuel processors to generate H2 for portable fuel cells [1,2]. The volume and mass of these processors has been limited by the performance of the catalysts. This paper describes integration of highly active and selective autothermal reforming, water gas shift and preferential oxidation catalysts into a thermally integrated, micro-channel reactor system capable of producing 1 kW of H2-rich gas for a proton exchange membrane (PEM) fuel cell. The catalysts were coated onto microporous Fe-Cr metal alloy foams then placed into microchannels within the thermally integrated reactor system.

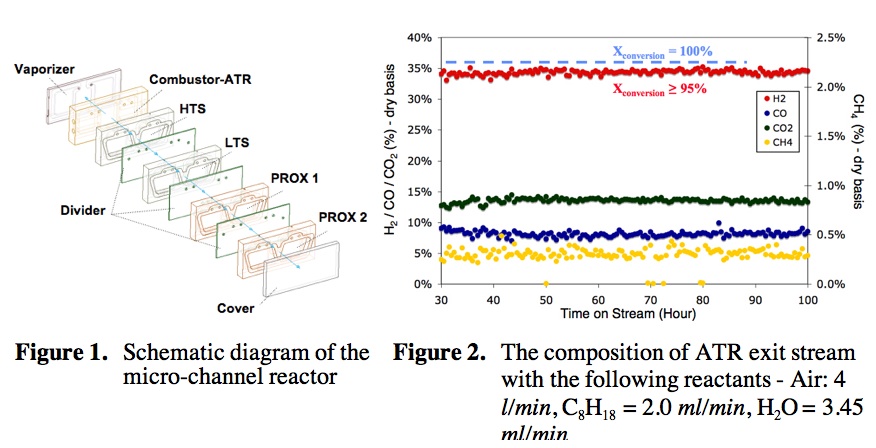

The internal structure of the microchannel based fuel processor is illustrated in Figure 1. In Figure 2, the performance of the ATR is illustrated: the H2-rich product gas contained ~35% H2 at 10 l/min of the total flow rate. The ATR performance was stable over the 100 hour long-term stability test and the hydrogen efficiency for the system exceeded 70%. These and other details regarding the catalysts and reactors for CO cleanup (water gas shift and preferential oxidation) will be described in the presentation.

[1] J.D. Holladay, E.O. Jones, M. Phelps and J.L. Hu, Journal of Power Sources 108 (2002) 21.

[2] Q. Ming, A. Lee, J. Harrison and P. Irving In Microreactor Technology and Process Intensification 2005, p 224.