548a Integrated Autothermal Micromembrane Fuel Processor for Fuel Cell Application

CH3OH + ˝. O2 → CO2 + 2H2 ΔHo=-192.3 kJ/mol ………………………(1)

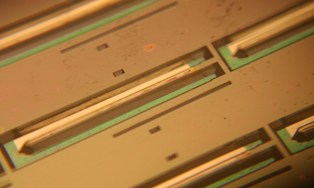

We present an integrated autothermal fuel processing microsystem consisting of hydrogen generation and catalytic combustion units [Figure 1]. The devices are fabricated using bulk micromachining techniques. Silicon based reactors ensure high thermal conductivity and help maintain autothermal operating conditions. The reformer consists of LaNiCoO3 based reforming catalyst and a ~ 200 nm thick palladium membrane for hydrogen generation and purification respectively, while the burner is loaded with supported platinum catalyst. The palladium membrane separation process implies an equilibrium amount of hydrogen remains in the exhaust gas. This hydrogen, along with unconverted methanol and carbon monoxide, can be burned by catalytic combustion to provide the necessary energy to make the overall hydrogen generation from methanol autothermal.

Prior to fabrication, detailed thermal analysis was carried out for feasibility studies. Based on these design considerations, generation 2 methanol reformers were fabricated.The performance of this integrated, autothermal hydrogen generation system in terms of energy efficiency and hydrogen production is characterized to identify regions of operation in which autothermal production of hydrogen is achieved.

References:

1. C. D. Baertsch, K. F. Jensen, J. L. Hertz, H. L. Tuller, S. T. Vengallatore, S. M. Spearing and M. A. Schmidt, “ Fabrication and Structural Characterization of Self-Supporting Electrolyte Membranes for a Micro Solid-Oxide Fuel Cell”, J. Mater. Res., 19, 2604 (2004). 2. Cowey, K., K. J. Green, Mepsted, G. O and Reeve, R. "Portable and Military Fuel Cells" Curr. Opin. Solid State and Mater. Sci., 8, 367 (2004) 3. Richardson, B. S., Birdwell, J. F., Pin, F. G., Jansen, J. F. and Lind, R. F. “ Sodium Borohydride Based Hybrid Power System”, J. Power Sources, 145, 21 (2005). 4. Bououdina, M., Grant, D. and Walker, G. “Review on Hydrogen Absorbing Materials- Structure, Microstructure, and Thermodynamic Properties”, Int. J. Hydrogen Energy, 31, 177 (2006).