116c The Microscopic Study of Granulation Mechanisms and Their Effect on the Non-Uniformity of Granule Properties

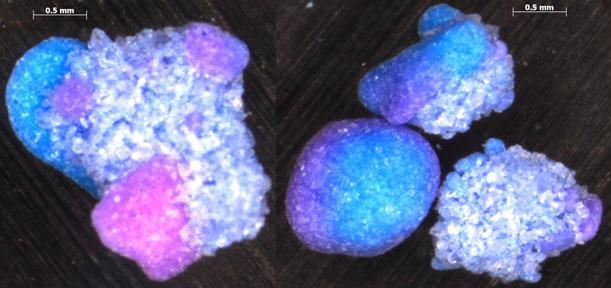

The granulation process is important in a wide range of industries, especially pharmaceuticals, foods and chemicals. Within the pharmaceutical industry there are some special desired properties of granulated products like reduced inhalation and explosion risks, homogeneity of the components, and controlled dissolution rates. Understanding of the fundamental processes to control granulation behaviour and to get the desired product properties is the important target for the researchers. The known granulation mechanisms include: wetting and nucleation, consolidation and growth, and breakage and attrition. These mechanims result in the different granule structures at different granulation times. They also lead to the non-uniformity in the granule properties, even within the same size range. This work based on a microscopic, or single granule scale, has been conducted to investigate the granulation mechanisms and the effect of these on the uniformity of the structure of granules, binder composition, porosity, dissolution rate and strength of granules within a given size class in high shear granulation. Based on the different structure of the granules at different massing times and the appearance of each structure, the results show how the granules coalesce, consolidate and break. It was also shown that there is a significant non-uniformity of the granules within size classes. This should be considered in the formulation, endpoint determination and control of high shear granulation. This also proves the importance of the individual rates of granule coalescence, consolidation and breakage on the granule properties. That helps to transfer the theoretical study into industrial practice.