406c Spatial Reconfiguration of Reactor Operation with Genetic Algorithms and Online Learning in Reactor Networks

This paper proposes an adaptive agent-based control system for a Continuous Stirred Tank Reactor (CSTR) network using a Genetic Algorithm (GA) based spatial reconfiguration technique. It also focuses on the online learning of the concentration of the dominant species in each reactor using Artificial Neural Networks (ANNs). The neural network algorithm is implemented in each reactor agent to capture the ongoing dynamics. Since this is an online learning, each individual data point does not provide sufficient information to update the weights of the network to reflect the dynamic oscillations happening during disturbances or applied step changes; however the online learning algorithm is capable of following the concentration profile when steady state is reached. The importance of the learning of concentration profiles demonstrates itself by giving the opportunity of implementing control schemes without interrupting the operation of the reactor network and developing the strategies using the knowledge obtained from the neural network.

The operation of highly nonlinear networks may benefit from evolutionary self-organizing control because the optimal operating regime and the required control strategies may not be known a priori. Agent-based control systems provide the capability for localized and global control strategies that are both reactive in controlling disturbances and proactive in searching for better operational solutions.

Large-scale spatially distributed systems have the properties of being nonlinear and mostly having a high order. Therefore, they present a unique and difficult control challenge. The control structure, which has to be implied to those systems, has a tendency to include continuous and discrete elements. Additionally, the structure itself is generally both discrete and distributed. A flexible supervision and control system, which can deal with local and global challenges, can be a layered control structure containing complex arrays of sensors and actuators. So-called hybrid control systems combine process dynamics and discrete control elements by using multiple linear models at different operating points. One alternative approach is based on a hierarchical agent-based system with local and global control structures that has been demonstrated on a network of interconnected CSTRs.

The performance of the agent-based control approach is illustrated in a case study where the interaction front between competing autocatalytic species is moved from one spatial configuration to another in the network of CSTRs mentioned above. Finding and maintaining operating states that are both stable and efficient is an ongoing research challenge since the complex nonlinear interactions between reactors may lead to undesirable or even unpredicted behavior. What are needed are adaptive control systems that can self-organize into productive patterns and self-correct in the face of unexpected deviations.

If a control agent desires to change the dominant species within the reactor under its control, it must transport some amount of the desired species from a reactor to which it is connected. If none of the immediate neighboring reactors contains the desired species, then the agent must negotiate with several other agents on the network in order to move the species from a more distant reactor. To minimize the disturbance to the operation of the network as a whole, the control agent attempts to find the shortest path between itself and a reactor containing the species that it needs to change the dominant species of its reactor. A GA-based spatial reconfiguration technique has been implemented and embedded into control agents in order to provide the ability to transport the desired species across the network to the target reactor.

The GA-based agent attempts to identify the most favorable source reactor, both in terms of availability of the desired species and the proximity to the target reactor. The fitness value is calculated based on the distance that the species has to travel in order to reach the target reactor, the need and the magnitude of increase in the feed flow rate to the source reactor, the rate of increase in interaction between each reactor, and the difference between paths from the source reactor to the target. The source reactor and the path to the target reactor are chosen according to the best fitness value calculated to meet the objective of changing the dominant species in the target reactor to another desired one.

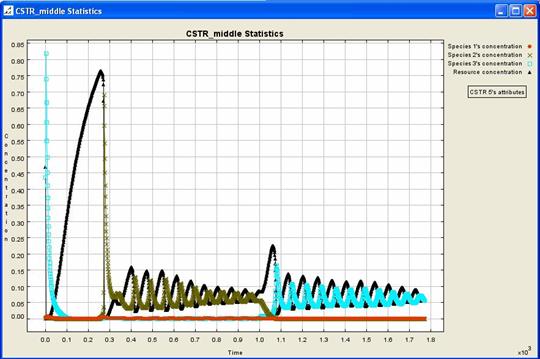

Figure 1(a) shows the initial conditions in a 3x3 network of reactors hosting three autocatalytic species. The objective set for the GA to achieve is to change the dominant species of the center reactor from species 2 to species 3. The time series plots for the concentrations are shown in Figure 2. After the network settles down from the initial startup at time 0, the GA agents are activated at tick 1000. The GA identifies a source reactor as the reactor just below the center reactor. Figure 1(b) shows the system after the parameters found by GA are applied to the system to change the dominant species of the center reactor. After the objective has been changed, the network parameters are reset to the initial conditions resulting in a new steady state concentration profile in the network (Figure 1(c)).

(a) (b) (c)

Figure 1 GA-based evolution of 2-D spatial concentration profile of the dominant species in each reactor, with red (dark gray) representing species 1, blue (black) species 2, and green (light gray) species 3

Figure 2 Resource and species concentrations in the center (target) reactor.

The 3x3 reactor network is for illustrative purposes. The presentation will provide results for networks of different sizes. It will also include the graphs for learned dominant concentrations.