677f Spray Drying Cellular Material for Long Term Storage

Spray Drying of Cellular Material for Long Term Storage

Yun-Ling Wong1, Samantha Sampson2, Andre Germishuizen1, Sunali Goonesekera2,

Barry Bloom2 and David Edwards1

1 Harvard University- Division of Engineering and Applied Sciences Cambridge, MA 02138

2Harvard School of Public Health- Department of Immunology and Infectious Diseases Boston, MA 02115

Abstract Summary:

Dried forms of model bacteria were prepared via spray drying with manipulation of formulation characteristics and especially the osmotic pressure on the bacteria. We find that by reducing osmotic pressure dry bacterial powders with excellent properties can be obtained. These powders also demonstrate the potential for good room temperature stability.

Introduction:

Vaccines for infectious diseases such as tuberculosis (TB) often require the drying of membrane-based materials such as bacteria. These materials are normally dried through lyophilization, which is both costly and can lead to the inactivation of 50% to 90% of bacterium or cellular material [1]. An alternative method to lyophilization is spray drying, a standard pharmaceutical process with several important advantages to lyophilization [2]. Previous efforts to spray dry live organisms such as yeast [3], blood cells [4] and other bacteria [5] demonstrated the ability to spray dry these materials with limited activity or stability. In this study, we aimed to develop methods and conditions conducive to producing dried bacteria and cellular material with high viability. This method allows for aerosolization of bacteria, allowing delivery via the pulmonary route.

Experimental Methods:

We prepared model bacterial powders based on Mycobacterium smegmatis, using a Buchi® Mini-Spray Dryer B-290 with Masterflex® L/S pumps to control feed flow rate. Inlet temperatures were varied between 100˚C-150˚C with outlet temperatures averaging around 50˚C-55˚C. We investigated the use of various excipients including lactose, leucine and trehalose with surfactants including Pluronic-68 and Tyloxapol. Viability was determined using conventional plating methods. Powders were characterized by measuring water content, tap density and particle size distribution. Water content was determined using a thermo-gravimetric analyzer Q50 (TGA) by TA Instruments. Tap density was determined by Varian Tap Density Analyzer. A viable Andersen Cascade Impactor (ACI) by Copley was used to determine the particle size distribution. Powders were visualized by environmental scanning electron and fluorescence microscopy.

Results and Discussion:

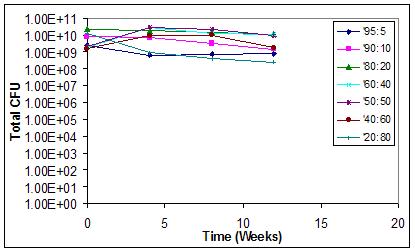

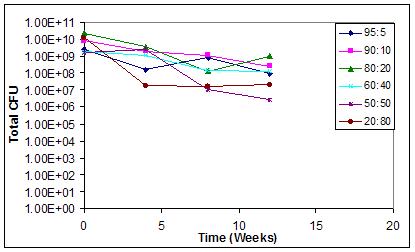

The dried model bacteria can be formed with high viability and potential long term stability. We found that the addition of cryoprotectant material, as usually added to spray dried bacteria, diminishes activity. Various ratios of bacteria were spray dried to study viability and powder characteristics over time. Each of these powders were placed under various stress conditions to determine the effect of various ratios of M. smegmatis on long term stability. Powders were placed with tightly sealed packaging in 4˚C at 0% RH, 25˚C at 60% RH, and 40˚C at 75% RH. Figures 1 and 2 below show the effect of these conditions on viability versus time at 4˚C at 0%RH and 25˚C at 60% RH. High viability is maintained independent of the ratio of bacterium to excipient over the twelve weeks tested, with the lower bacteria fraction powders showing better shelf stability at 25˚C than the highest bacteria fraction powders.

Figure 1. Viability of bacterium over time at various ratios of bacterium in dried powder formulation in 4˚C at 0%RH.

Figure 2. Viability of bacterium over time at various ratios of bacterium in dried powder formulation in 25˚C at 60% RH.

We visualized the powders using green fluorescence protein (GFP-labeled) M. smegmatis to determine that the live bacterium is associated with the particle as shown in Figure 3. The overall green fluorescence of the particles demonstrates that the bacteria are well-distributed throughout the powder.

Figure 3. GFP-labeled live bacterium associated with dried particles.

We also found that the addition of lypophilic coating material to the bacteria can further add to room temperature stability, apparently through prevention of diffusive drainage of free water from inside the dried cells (results not shown).

Conclusion:

We have successfully spray-dried cellular material with high activity and good shelf life stability. The novel process and compositions of our work points the way to a robust, low-cost method for achieving room temperature stable vaccines for diseases such as TB.

References:

1. Heller, M.C., J.F. Carpenter, and T.W. Randolph, Protein Formulation and Lyophilization Cycle Design: Preventation of Damage Due to Freeze-Concentration Induced Phase Separation. Biotechnology and Bioengineering, 1999. 63(2): p. 166-174.

2. Maa, Y.-F., Phuong-Anh Nguyen, Kin Sit, Chung C Hsu, Spray-Drying Performance of a Bench-Top Spray Dryer for Protein Aerosol Powder Preparation. Biotechnology and Bioengineering, 1998. 60(3): p. 301-309.

3. Luna-Solano, G., MA Salgado-Cervantes, GC Rodriguez-Jimenes, MA Garcia-Alvarado, Optimization of brewer's yeast spray drying process. Journal of Food Engineering, 2005. 68(1): p. 9-18.

4. DeRouchey, J.M., et al., Comparison of Spray-dried Blood Mean and Blood Cells in Diets for Nursery Pigs. Journal of Animal Science, 2002. 80: p. 2879-2886.

5. Amiet-Charpentier, C., P. Gadille, and J.P. Benoit, Rhizobacteria Microencapsulation: Properties of Microparticles Obtained by Spray Drying. Journal of Microencapsulation, 1999. 16(2): p. 215-229.