162l Cracking in Wet Coatings of Aqueous Colloidal Dispersions

Traditional paints and coating formulations contain organic solvents that plasticize the dispersed polymer particles to achieve film formation. However, environmental issues concerning volatile organic chemical emissions have made latex an attractive alternative to these traditional formulations (Keddie, 1997). When a thin film of latex is applied to an impermeable substrate, evaporation of water consolidates the particles into a closed packed array. Further evaporation of water generates stresses that deform the particles in the film (Tirumkudulu and Russel, 2004). Depending on particle glass transition temperature (Tg) and the ambient temperature, the particles may either coalesce to form a homogeneous film or may lead to cracking. If the glass transition temperature of particles is higher than the ambient temperature, the final film is found to contain large number of cracks in it.

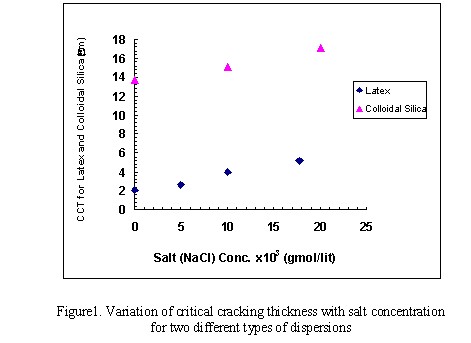

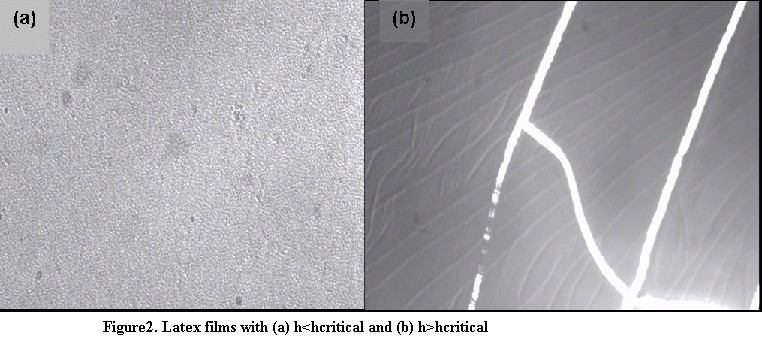

In the present work, we show that there is a critical film thickness beyond which the capillary stresses induced during drying result in film cracking. Further, it was found that the critical film thickness was determined by the maximum capillary pressure. Here, we present the critical cracking film thickness measurements for two different types of dispersions at various salt concentrations. The first one was a latex dispersion containing spherical styrene/butadiene random copolymer particles of diameter 250nm and glass transition temperature 650C. The second dispersion consisted of rigid colloidal silica spheres of diameter 330nm suspended in water. It is found that the measured critical thickness values are much larger than those predicted by the model of Tirumkudulu and Russel (2005). To resolve this discrepancy between the measurements and the model predictions, we reconsider the criteria employed to derive the expression for critical cracking thickness (CCT). Specifically, the model assumes that at CCT, the particles undergo complete deformation without inducing a crack. This, however, requires the capillary pressure to be of the order of 10(gamma/R), where gamma is the interfacial tension between air and water and R is the particle radius. An experimental technique devised to measure the maximum capillary pressure showed that the measured value for silica dispersion was almost two orders of magnitude lower than 10(gamma/R). Finally, a modified analysis based on the measured value of maximum capillary pressure resulted in the critical cracking thickness values close to the experimental observations. In figure 1, the variations in critical cracking thickness with salt concentration for two different dispersions have been presented. Further, figure 2 shows the optical micrographs of a crack free and a cracked latex film.

References

Keddie, J. L., “Film formation of latex”, Material Science and Engineering, 21, 101-170 (1997).

Tirumkudulu, M. S. and Russel, W. B, “Role of capillary stresses in film formation”, Langmuir, 20 (7), 2947-2961 (2004).

Tirumkudulu, M. S. and Russel, W. B., “Cracking in drying latex films”, Langmuir, 21 (11), 4938-4948 (2005).