201g High-Speed Microstructuring of Polymer Films Driven by a Fluid Dynamical Instability

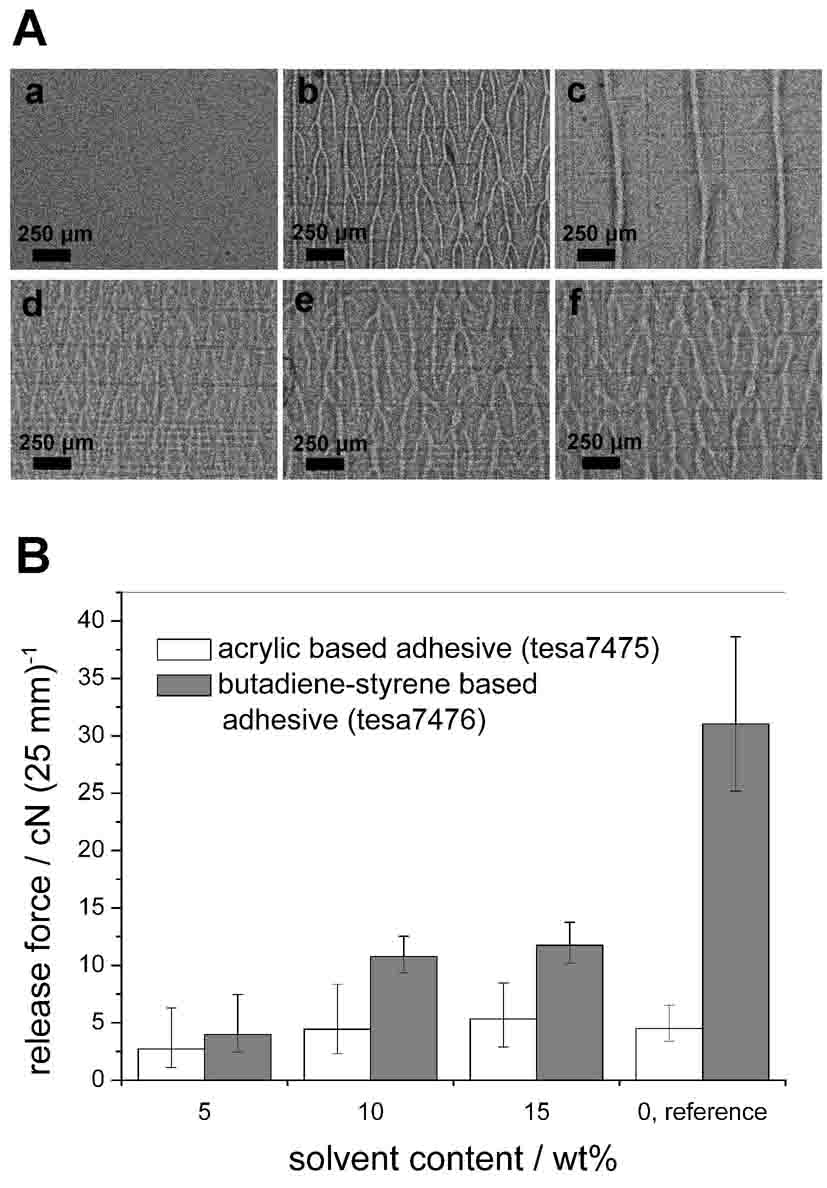

Methods: Thermally curable PDMS resin was rheologically modified by the addition of highly agglomerated, aerosol-derived silica and resulted in a Herschel-Bulkley fluid. Application of the modified siloxane in a roll coating process resulted in a fluid dynamical instability at high capillary numbers promoting the spontaneous formation of randomly branched surface structures (Fig. A). The shear-thinning properties of the nanoparticle doped PDMS resin were adjusted as to preserve the wet, structured coating during the following thermal curing step. The highly regular pattern was characterized in terms of averaged branch width and could be controlled from micro- to millimeter size by adjusting coating roll velocity and roll gap distance which directly influenced the grammage of the cured silicone loading.

Results: The adhesive properties of the structured coating were compared to unstructured conventional silicone coatings by measuring the release force of pressure sensitive adhesives. For rubber-based tape the release force of patterned PDMS was reduced by a factor of up to eight if compared to smooth reference silicone (Fig. B).

[1] G.V. Gordon, T.M. Leaym, M.J. Owen, M.S. Owens, S.V. Perz, J.L. Stasser, J.S. Tonge, M.K. Chaudhury, K.A. Vorvolakos, and H.Q. She, Adhes. Age, 43, 41-44, 2000. [2] S. Loher, T. Maienfisch, S. Bokorny, W. J. Stark, Polym. Eng. Sci., in press, 2006. [3] S. Loher and W. J. Stark, Method for the application of a structured coating upon a smooth surface, PTC patent application, September 2005.