486a Field-Driven Surface Biofunctionalization of Electrospun Fibers

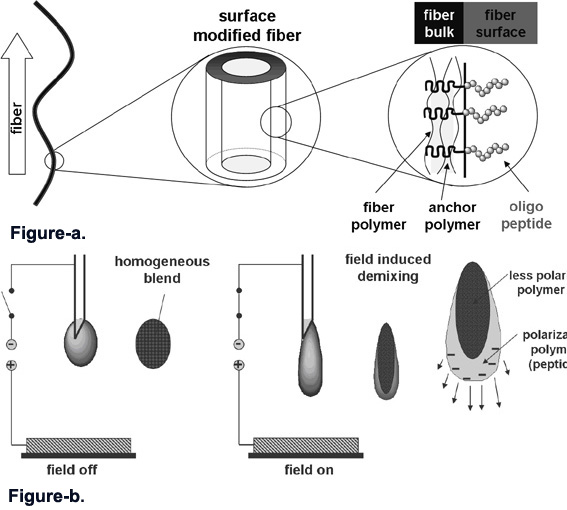

Surface modification of nanofibers with bioactive functional groups has become an important research topic in the past decade as an attractive and relatively straightforward avenue to bioactive textiles and biomedical materials (e.g., tissue scaffolds). We have developed a single-step route for the production of biofunctionalized synthetic fibers by incorporating sequence-defined oligo-peptides onto the surface of electrospun fibers during electrospinning, as schematically illustrated in Fig. a-b. Conventional polyethylene oxide (PEO), an established biomaterial, has been electrospun in conjunction with novel synthetic-bioorganic PEO-oligopeptide block copolymers of the form PEO-b-(Glu-Glu-Ser)3. X-ray photoelectron spectroscopy (XPS) results indicate that field-driven surface enrichment of the block copolymer is 5 to 10 times greater than in the bulk. Although fibers generated from aqueous solutions with 2 to 4 wt% polymer show similar trends in terms of surface enrichment, the fibers produced from the 3 wt% polymer solutions consistently exhibits the highest concentration of copolymer at the surface. Scanning electron microscopy (SEM) and confocal-Raman atomic force microscopy (CR-AFM) have been used to investigate the morphology and crystallinity of the resultant fiber mats. To discern the role of copolymer on electrospinning, the influence of the block copolymer on solution viscosity and conductivity has also been investigated.

Attached figures: a. Microstructure of the surface-functionalized fiber; b. Proposed mechanism of electrospinning a fiber containing a synthetic-bioorganic hybrid copolymer