TMM4175 Polymer Composites

Definitions and classification¶

A composite material is one that consists of two or more materials, or phases. The simple and straightforward definition needs however further specifications and/or limitations for practical engineering use: 1) The different phases of a structural composite have distinct physical and mechanical properties, and 2) the characteristic dimensions are much larger than molecular dimensions.

Without the limitations given above, most substance will fall into the basic definition of composites simply by increasing the resolution down to molecules and atoms.

A material is homogenous if its properties are the same at every point. The concept of homogeneity is associated with the scale or resolution as well as the properties involved. Therefore, a material can for instance, be considered as homogenous on a macroscopic level while being heterogeneous on a microscopic level. This is often the case for fiber composites and particle reinforced plastics where the fiber diameter and particle size is just a few micrometers while the resolution of the engineering problem typically is in the millimeter range.

Classification¶

There are several approaches for classifying composite materials, where the different approaches usually reflects the scope and perspective of authors. Typical textbooks in general material science such as [1] tends to classify the composites by micro and macro-structural arrangements, while specialized textbooks on composites [2] typically add detailed sub-categories based on the types of constituent materials and the specific applications of the material. The following list of categories is not particularly ordered nor is it complete. Rather, these terms and concepts are often encountered in the literature and therefore, a brief description and discussion is warranted:

Natural composites: Composites are not original human inventions. For instance, wood, which consist of cellulose fibers and a lignin matrix is a typical natural composite material. Other examples includes bones, tissues and even rocks as aggregates of various minerals.

Micro-composites include many metallic alloys, fiber and particle reinforced polymers and more generally, any substances where different unique constituents can be identified on the micro scale.

Macro-composites include laminated structures, steel reinforced concrete and other combinations of materials where the different constituents can be identified by the bare eye. Laminated structures play an important role in structural composite design and engineering and are covered comprehensively in TMM4175 Polymer Composites.

Nano-composites is a rather ambiguous term since virtually all materials, according to the definition, can be put into this category since we find atoms and molecules on the nano-scale. In practice, however, a nano-composite is understood as the solid combination of a bulk matrix and nano-dimensional phase(s) differing in properties due to dissimilarities in structure and chemistry [3].

Polymer matrix composites have thermoplastic or thermoset matrices combined with any compatible reinforcements

Polymer composites are for all practical purposes synonymous to polymer matrix composites.

Metal matrix composites consist of metal or alloy reinforced with compatible materials such as boron and ceramic fibers

Ceramic matrix composites have ceramic matrices and are typically reinforces with ceramic fibers.

Fibrous composites are, as the term obviously suggests, composites where fibers are the reinforcing components of a matrix [4].

Advanced composites is another ambiguous concept. Typically, you may substitute advanced with complicated and/or expensive to make and thereby obtain a more candid understanding of the term.

Hybrid composites are combinations of arrangements and/or materials that are not easily described by the other categories.

Micro-composites¶

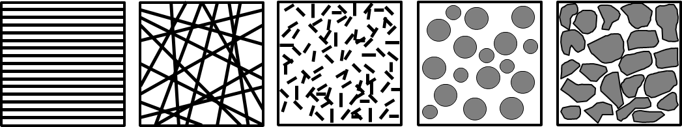

Conventional composite design and engineering will most of the time involve one or several materials that fall in the category micro-composites. These are usually classified based on the shape and arrangement of the reinforcements.

Continuous fiber composites: The fibers are continuous, or at least very long, and may be aligned or randomly oriented.

Short fiber composites: The length of the fibers is on the same scale as the diameter, and they are usually randomly oriented. A more common description of such materials is, however, fiber filled polymers or plastics when the matrix is a polymer.

Particulate composites may contain spheres, plates and sheets or irregular particles. An example of the latter is the hard and brittle tungsten carbide particles in a ductile cobalt matrix used for cutting tools.

References and further readings¶

- Callister, William D., and David G. Rethwisch. Materials Science and Engineering. 9th Ed., SI Version. ed. Hoboken, N.J: Wiley, 2015.

- Daniel, Isaac M., and Ori Ishai. Engineering Mechanics of Composite Materials. 2nd ed. New York: Oxford University Press, 2006.

- https://en.wikipedia.org/wiki/Nanocomposite

- Herakovich, Carl T. Mechanics of Fibrous Composites. New York: Wiley, 1998.

Disclaimer:This site is about polymer composites, designed for educational purposes. Consumption and use of any sort & kind is solely at your own risk.

Fair use: I spent some time making all the pages, and even the figures and illustrations are my own creations. Obviously, you may steal whatever you find useful here, but please show decency and give some acknowledgment if or when copying. Thanks! Contact me: nils.p.vedvik@ntnu.no www.ntnu.edu/employees/nils.p.vedvik

Copyright 2021, All right reserved, I guess.